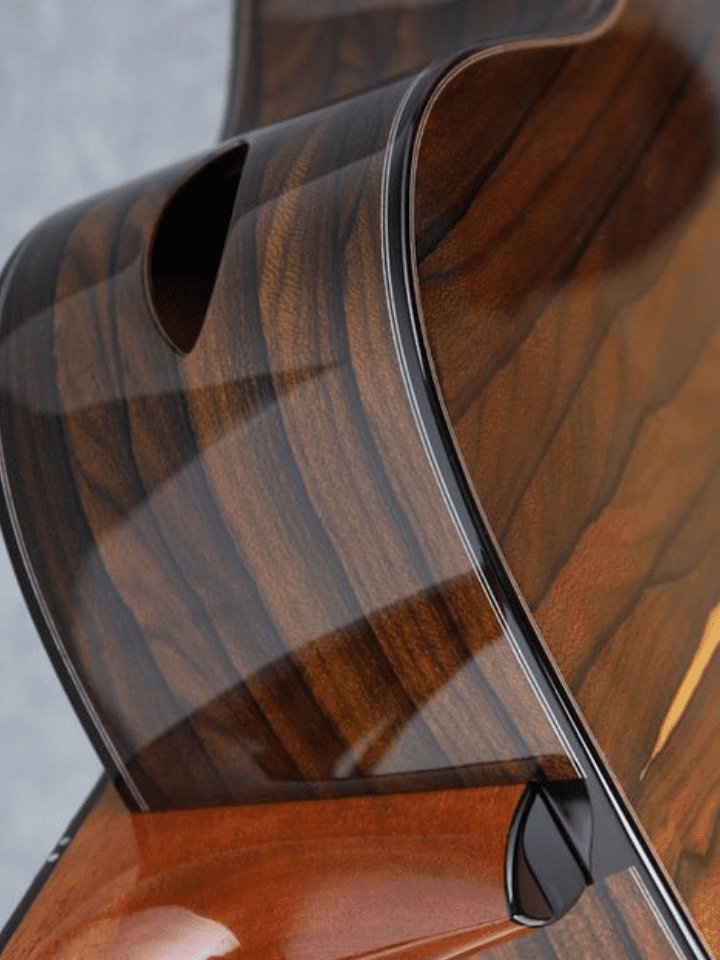

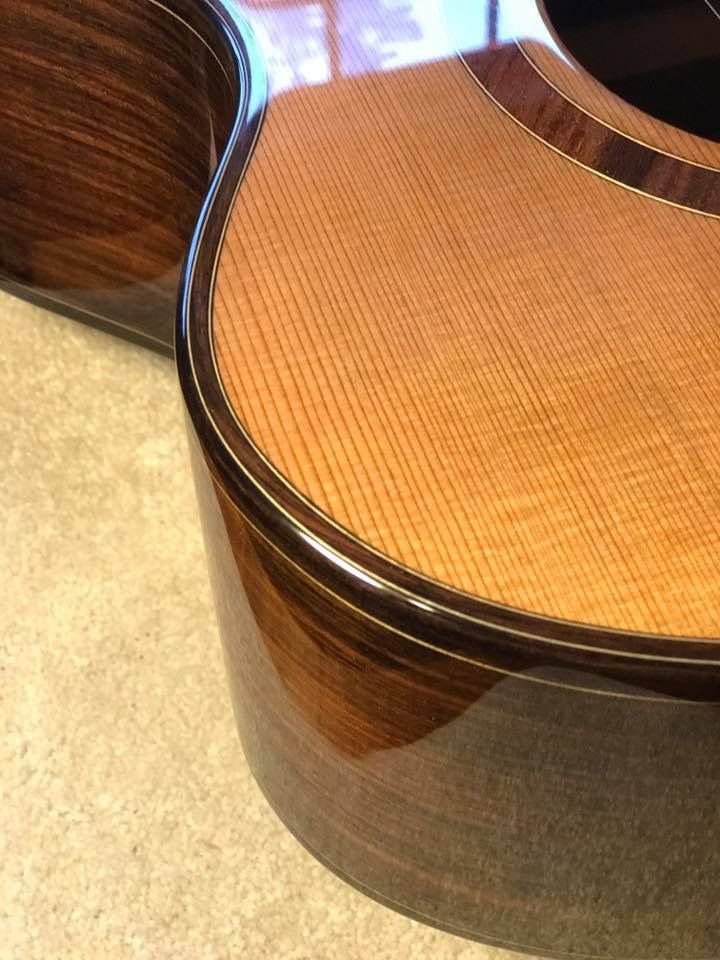

High-gloss surfaces for instruments or interior design

Polyester paints for wood surfaces

Excellent color depth

Excellent, unmistakable gloss

Very high scratch resistance

Flexible and shock-resistant: resists cracking during production, drilling, milling or screwing

High solids content: more than 70% during application

Consistently high quality (batch-to-batch consistency)

The polyester coating generally refers to the polyester formed by the polycondensation reaction of polybasic acid and polyol (including partially unsaturated polybasic acid) and then mixed with a comonomer, which is crosslinked and cured under the action of initiator and accelerator to form a coating film. Coatings are customarily called polyester coatings

Polyester paints for pianos are particularly scratch-resistant, making wood surfaces retain their gloss for decades.

The coatings not only protect wood instruments of any style, but can also be used for high-quality interior woodwork designs on artwork or stores.

Specification

|

Base Material |

Oil Based |

|

Coverage |

110- 130g/㎡ |

|

Substrate Condition

|

Bare Wood, Finished Wood, Old/Reclaimed Wood, Stained Wood, Unfinished Wood |

|

Package |

3.5kg/20kg |

|

Color (after curing) |

Transparent/white color |

|

Dry time |

Packing time: > hour (Temperature: 15-40°C, humidity:35%-80%) |

|

Shelf life |

6 months |

|

Suitable spraying method |

Spray |

|

Ratio |

Polyester : |

The paint film of polyester paint is hard, wear-resistant, water-resistant, heat-resistant, resistant to dilute acids, alkalis, solvents, oils, and other chemicals, and has good insulation.

The appearance of the paint film is plump and thick, with an extremely high gloss.

Issues that need special attention:

Pay attention to the paint ratio and reasonable paint mixing

Sufficiently skilled in the use of spray guns

Improve the conditions of the construction site

Use appropriate thinners to tune the paint

Instructions:

1. If the surface of the base material is too rough, it must be pre-treated by dry grinding.

2. Before spraying PE primer, the substrate must be effectively sealed. Use our factory's sealing primer to apply once, then lightly polish after drying, which can effectively remove wood thorns, improve the hardness of the substrate, and strengthen the adhesion between the substrate and the primer. Reducing the amount of primer used without increasing the total cost of the entire set of materials can be said to kill two birds with one stone.

3. Construction process: base material → grinding → sealing primer → grinding → spraying PE primer → grinding → spraying various PU or PE topcoats.

4. PE primer series consists of multiple components: primer, accelerator (blue water), initiator (white water), thinner. They are packaged and sold separately. When used, mix according to the correct procedure and weight ratio, filter and spray.

5. Mixing procedure: Divide the primer used into two equal parts. Add the initiator (white water) and a certain amount of thinner to one part and mix well to form A; add the accelerator (blue water) and a certain amount of thinner to one part and stir. Divide into B and set aside. Before spraying, take equal amounts of A and B and mix well. After filtering, spray immediately.

6. Mix A and B in equal amounts each time and stir well. After filtering, spray it on the substrate that has been sealed with sealing primer. Generally, spray two "crosses". After each coat of paint (a "cross"), there is usually an interval of 5-10 minutes before the next coat of paint can be sprayed. When the ratio is correct, the finger-touch drying time should not exceed 40 minutes (temperature 25°C). When large errors occur, repeated inspections should be made and the ratio should be adjusted to normal.

Application

including floors, doors, furniture and more.

FAQ

Transportation conditions: temperature 5 ~ 40°C,storage conditions: 5 ~ 35°C。

Store in a cool, dry and ventilated place, away from sunlight, rain, high temperature or freezing.

Exceeding the specified temperature will shorten the storage period.

Please keep unused paint in a sealed container and keep it out of reach of children and other unrelated persons.

Never pour this product down drains or drains. Disposal of this product must comply with local environmental regulations.